Optical allusions

10 December 2004Experiments have been undertaken in Sweden that utilise optical fibre technology to measure the problem of seepage in a series of embankment dams, explain Dan Watley and Sam Johansson

THE measuring of seepage and movement is a fundamental part of dam surveillance, and is undertaken in some way by the majority of dams in the world. Recent developments in distributed measurements using optical fibres have radically improved the ability to achieve accurate results, mainly due to the technology’s ability to measure seepage and movements at every metre along the dam. Since 1999 HydroResearch Sam Johansson AB (Ltd) and Sensornet Ltd have installed optical fibres in nine embankment dams in Sweden (Lövön (1998, Sädva (1999), Aitik (2000), Ajaure (2001), Vargfors (2001), Hylte dam and dyke (2002), Suorva West (2003), Suorva East and Sägviksdammen (2004), Bastusel 3 dams (2004) and Gallejaure 4 dams (2004)), using different installation techniques depending on the dam1,2. These include: embedding of the fibre inside the dam (at new constructions); in the crest during raising of a dam; within new toe berms at upgrading work and just downstream of the dam toe or vertically in standpipes. Once the fibre is installed, seepage and movement can be measured as periodically or continuously as is required. Four permanent surveillance systems for monitoring seepage are planned for 2005, and another five fibre installations. The installation cost, including the cable, is typically around Euro 10-15/m (US$13-20/m). Optical technology

Distributed sensing takes advantage of the fact that the reflection characteristics of laser light, travelling down an optical fibre, vary with temperature and strain. The sensor consists of a length of standard telecoms optical fibre, normally housed in a protective cable. The measuring instrument uses a laser to fire pulses of light into the sensing fibre. A detector measures the reflections from the fibre as the pulse of light travels down its length. Measuring the change in power and colour of these reflections against time allows the instrument to calculate temperature and/or strain at all positions along the fibre. The key feature is that the fibre itself is the sensor and it can be used to measure along its entire length.

Sensornet currently offers a range of measurement instruments, including the Sentinel DTS that can measure temperature to a resolution of 0.01°C over a distance of 10km with a spatial resolution of just 1m. This means that for a 10km length of cable you have the equivalent of 10,000 point sensors. Sensornet also provides the DTSS (Distributed Temperature and Strain Sensor)3, a pre-production instrument capable of measuring strain to a resolution of 10µe, independently of temperature, over a distance of 10km again with a spatial resolution of 1m.

To complement the instruments, HydroResearch and Sensornet have developed and tested an optical cable specifically for dam installations. The cable contains two single mode fibres and two multimode fibres, allowing connection to both the Sensornet Sentinel DTS, for very fine resolution temperature monitoring, and to the Sensornet DTSS, for monitoring of strain. The cable is strong enough to withstand the high levels of compaction experienced during installation into a dam.

Temperature changes

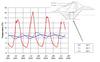

Seasonal temperature variations occur in all surface water such as lakes, reservoirs and rivers, causing changes in the level of seepage water that passes through a dam throughout the year. The magnitude of the seasonal temperature variation seen in the dam is correlated to the seepage flow through the dam, as shown in figure 1. A constant temperature will be a sign of a small seepage, while large seasonal variations may indicate significant seepage. The response depends mainly on the seasonal temperature variation in the reservoir and the distance from the reservoir to the measuring point. Impact from the seasonal air temperature variations will also influence if the measuring point is located close to the surface. Hence, seepage detection and quantification can be made by temperature measurements in the dam. The method was initially developed by Kappelmayer (1957)4. Further research concerning evaluation and monitoring was carried out during the 90’s by Johansson5,6 supported by Swedish Electrical Utilities´ R&D Company Elforsk. An active method for seepage detection using heating was also developed by Dornstädter7.

Distributed Temperature Sensing using optical fibre offers an extended information level compared to information achieved from single temperature sensors. The information can be compared with measurements in open standpipes, giving vertical temperature profiles that have proved useful. The fibre can be installed both along the dam and vertically in open standpipes.

Regular distributed temperature measurements are made at the Sydkraft Vattenfraft AB owned Hylte dam, where a 2.3km long cable was installed during 2002 at the toe of the dam and the dyke. Since then a series of five measurements have been taken. The seepage flow through the dam has been evaluated, from the measured temperatures, as a flow varying between 5 and 15x106 m3/sec using HydroResearch’s seepage calculation model, 'DamTemp', developed with the Dam Safety Interest Group.

During August 2004 an experiment took place to demonstrate the ability of HydroResearch and Sensornet to detect a concentrated leakage at Hylte dam. A length of hose was used to siphon water from the reservoir to infiltrate the downstream toe, about 1m upstream the cable, which is buried roughly 0.8m below the soil surface. The infiltration lasted for 18 hours, with a flow rate of 0.07l/sec. The water level in the toe rose by about 0.2m during the test, a clear indication that some of the infiltrated water had passed above the cable.

A small but significant temperature change was observed at cable marking 1906 and 1907 after about seven hours, which finally increased to a change of 0.2ºC over a 3m length – the largest along the entire cable where it is located in the dam. The leakage was more clearly identified by calculating the daily temperature trend (figure 2). This initial test clearly demonstrated that a fibre installed below the ground water table in the downstream toe of the dam provides excellent possibilities to detect small seepage changes. Continuous measurements are planned for 2005 to improve both the absolute and the relative accuracy.

Measuring strain

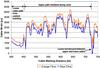

Since 1999, within research projects funded by Elforsk8,9, HydroResearch and Sensornet have also been developing techniques for monitoring movements in a dam. In September 2004, the first distributed measurement of strain in an embankment dam was undertaken, carried out at Vattenfall Vattenkraft’s Ajaure dam in Sweden. The aim is to compare the measurements taken during September, at full reservoir level, with measurements to be taken this spring at low reservoir level. A comparison of the two measurements will show the change in deflection of the dam caused by the different reservoir water levels.

The sensing cable was installed in the crest of the dam during 2001 when the crest was raised according to the new Swedish Guidelines for Floods10. Three inclinometers were also installed in order to detect movements in some sections. The sensing cable, a total length of 1122.5m with an effective monitoring length of 320m on each level within the dam crest, was installed at two levels along the dam in order to detect movements between the inclinometers. The fibre is installed in a loop configuration, which means that each of the two strain fibres in the cable can be measured in either direction around the cable path. On its way to the dam the cable passes beneath a bridge over the spillway where the cable can be exposed and allow experiments and testing (figure 3).

The first strain measurements taken during September are shown in Figure 4 for the upper cable path. There is agreement between the two cables measuring the strain variations measured on the two embedded fibres; any difference between them relates to differences in manufacture and can be corrected for. It should be noted that the measured strain varies considerably along the installed length of cable. This variation arises from the dam construction process, where the soil has been compacted on top of the cable causing strain variations in the cable. However, these variations cause no problem since this set of measurements will act as a reference to which future measurements will be compared. The Sensornet DTSS is capable of resolving changes as small as 10µe in every metre of a 10km fibre cable.

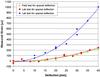

To complement these first measurements of the cable, an experiment was performed at the same time to determine the size of deflection, or dam movement, that could be detected by the Sensornet DTSS. The experiment was undertaken on a section of the dam cable suspended loosely from underneath a road bridge over the spillway. The cable was fixed with clamps at two positions 4m apart horizontally, and pulled tight. It was then deflected downwards at its mid point using a number of aluminium spacers, each 5mm thick, as shown in figure 5.

The experiment was repeated at the Sensornet Laboratory for both 4m and 2m separation between the cable clamps. The results of all three tests are shown in figure 6 for a range of deflections. A quadratic trendline has been fitted to each data set, showing excellent agreement between the field and laboratory measurement for 4m spacing between the cable clamps. The 2m spacing data points show a good quadratic fit and a magnitude four times that of the 4m spacing data sets, agreeing well with theory. The 2m clamping interval is a closer representation of the behaviour of the cable, since it is effectively clamped at very small intervals due to the surrounding material of the dam.

These tests have demonstrated that a deflection of the dam by just 5mm will be detectable. The Sensornet DTSS has a spatial resolution of 1m, meaning that a measure of strain is provided for every single metre of cable installed in the dam. Hence, small movements of the dam can be both detected and located to any position along the installed cable. This will provide important information on the overall performance of a dam at different loads. Eventual weaknesses in the dam structure will also be detected.

Conclusions

Distributed monitoring of temperature and strain will improve the understanding of the behaviour of all kinds of dams, and these first examples from installations in embankment dams clearly indicate the potential of the fibre optic technology. If optical fibres are installed along a dam toe they can locate anomalous seepage areas, and estimate the seepage flow after some short measurements (normally a couple of days). Longer, or repeated, measurements, will improve the detection capability and the accuracy of the seepage flow evaluation. The first strain measurements and test at Ajaure dam indicate that Sensornet’s DTSS will be a valuable tool to detect movements as small as 5mm in dams, and the next set of measurements to be taken in the spring is expected to provide further confirmation of this. The test conducted at Hylte, and experience from other dams, confirms the effectiveness of temperature measurement for detecting, locating and quantifying seepage changes. The best application of the method is long term monitoring, where slow and small seepage flow changes can be detected.

Author Info:

Sam Johansson works for HydroResearch Sam Johnsson AB, Sweden. Phone: +46 8 756 4950. sam.Johansson@hydroresearch.se. www.hydroresearch.se

Dan Watley works for Sensornet Ltd. Phone: +44 207 394 3555. dan.watley@sensornet.co.uk www.sensornet.co.uk